Products

Open cooling tower

Measurement Standard: According to national standard GB/T 7190.1-2018, cooling capacity should be ≥95%.

Category:

Open cooling tower

Keywords:

Open Cooling Tower

Open cooling tower Details

Basic Performance Parameters

Cooling Capacity

Measurement Standard: According to national standard GB/T 7190.1-2018, cooling capacity should be ≥95%.

Calculation Method: Cooling capacity = Cooling water flow × Specific heat capacity of water × Temperature difference (ΔT), typical temperature difference range is 3–15℃ (for example, when the flow rate is 100t/h, the temperature drop is usually designed as 5℃).

Water Flow and Temperature Difference

Standard Operating Conditions: Inlet water temperature 37℃, outlet water temperature 32℃ is a common engineering design benchmark.

Flow Range: Small and medium-sized open cooling towers are 10–1000m³/h, large open cooling towers >1000m³/h.

Structural Parameters

Parameter Category |

Technical Indicators |

Filler Type |

PVC film filler (increases water-air contact area, improves heat dissipation efficiency by 20–35%) |

Fan Configuration |

Axial flow fan (power and air volume matching, energy consumption accounts for about 60–70%) |

Spray System |

Multi-stage spray pipe + wide-angle nozzle (coverage exceeds 95%) |

Tower Body Material |

Galvanized steel (standard) or stainless steel (corrosion-resistant scenarios) |

Environmental Adaptability Parameters

Wet-bulb Temperature Influence

Cooling Range Index: The smaller the difference between the outlet water temperature and the wet-bulb temperature, the higher the cooling efficiency, typical cooling range ≤5℃.

Limit Operating Conditions: When the wet-bulb temperature ≥28℃, it is necessary to increase the fan power or use auxiliary heat dissipation devices.

Noise Control

Standard Requirements: Tower body noise at 1m ≤75dB(A), low-noise type can be optimized to within 65dB(A).

Energy Saving and Loss Indicators

Parameters |

Water and Energy Saving Cooling Tower |

Comparative Description |

Drift Rate |

≤0.5% (open type) |

|

Closed Cooling Tower Drift Rate |

0.05% |

|

Makeup Water |

1.24–2% of circulating water |

Closed cooling tower makeup water demand as low as 0.1–0.2% |

Comprehensive Energy Consumption Ratio |

0.12–0.18kW/(m³/h) |

Includes the total energy consumption of fans, water pumps and auxiliary equipment |

Operation and Maintenance Parameters

Water Quality Requirements

Requires regular treatment: Due to the direct contact between water and air, algae and scale are easily generated. It is recommended to check the pH value (6.5–8.5) and turbidity (≤20NTU) monthly.

Drainage system: An automatic drainage valve is installed at the bottom of the tower, and the impurity removal rate is ≥90%.

Anti-freeze Design

Optional configuration: Heating coil (keep water temperature ≥5℃) or drainage device (winter shutdown protection).

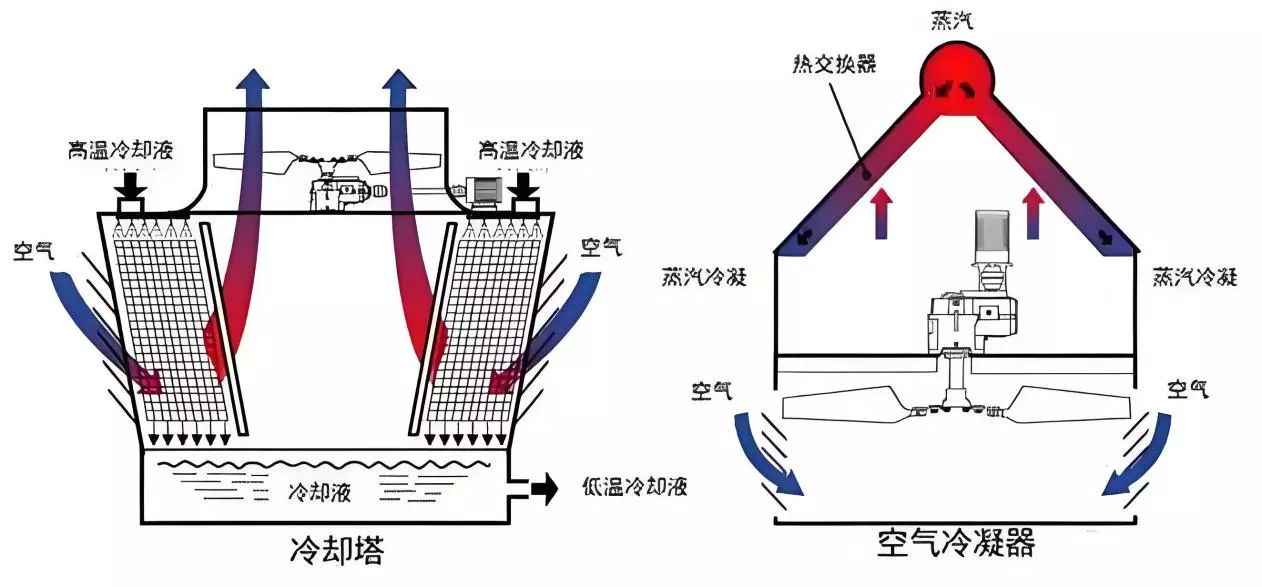

Equipment Diagram

Prev

Next

Prev

Next

Related Products

Online consultation

Contact Us

Address:Anqiu City, Weifang City, Shandong Province, China