Products

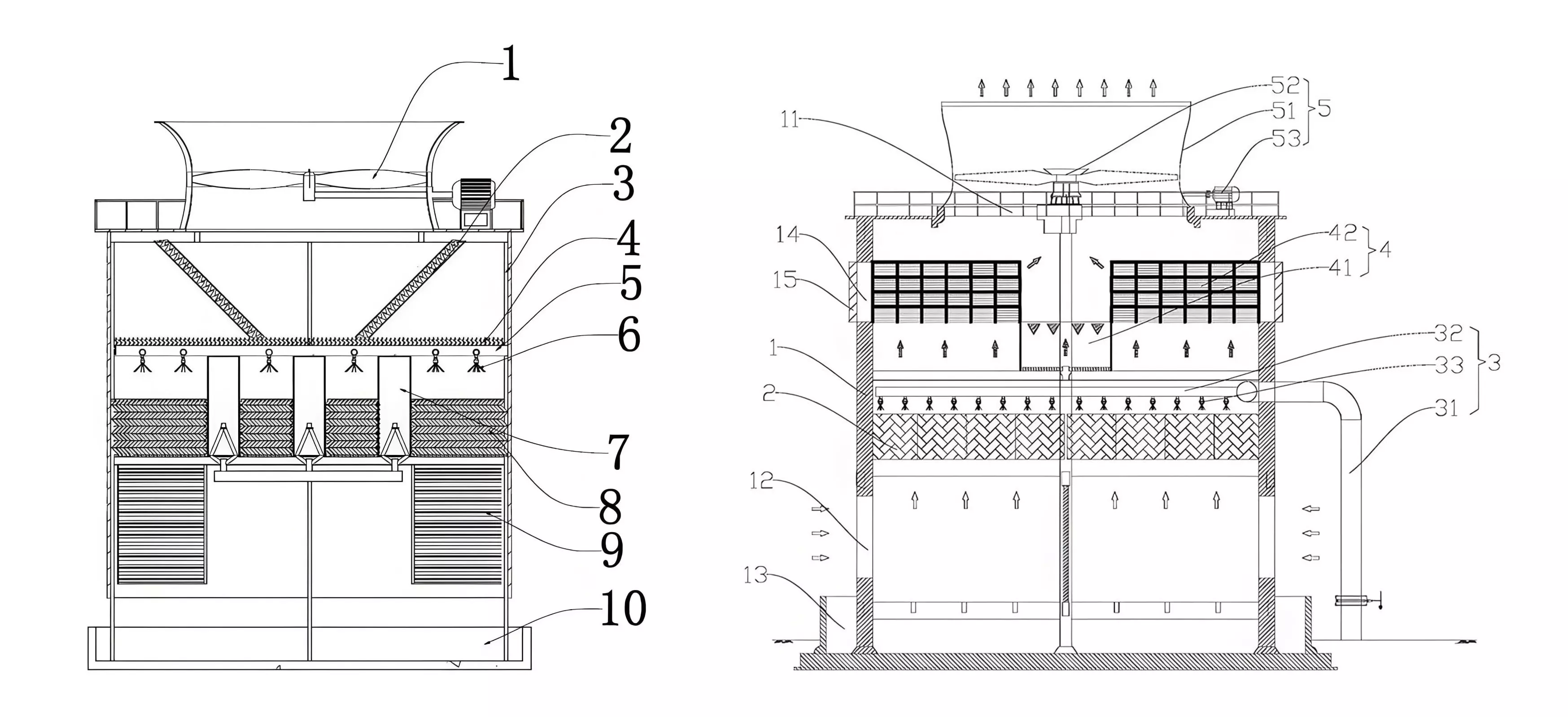

Energy-saving and fog-reducing cooling tower

Standard Model: 500-6000m³/h (Modular design, supports multi-tower parallel expansion)

Category:

Energy-saving and fog-reducing cooling tower

Keywords:

Energy-saving and fog-reducing cooling tower Details

Flow and Cycle Parameters

Single-tower cooling water flow range

Standard Model: 500–6000m³/h (Modular design, supports multi-tower parallel expansion)

Large industrial tower: Up to 5500m³/h (SCC-X series single module)

Pipe diameter and lift

Strong water pressure resistance, using diamond-shaped heat exchange modules to optimize water flow resistance

The water distribution system uses multi-layer low-pressure nozzles to ensure even distribution and water saving

Operating conditions and temperature parameters

Standard operating conditions

Temperature drop range: 5–10℃ (Adjust operating mode according to the season)

Wet-bulb temperature requirement: Design baseline generally ≤28℃

Maximum inlet water temperature: Supports 60℃ (Switch to conventional cooling mode in summer)

Environmental adaptability

Winter mode: Mix warm, humid air with dry, cold air to eliminate plume and save 15–20% water

Summer mode: Turn off the demisting module and prioritize cooling efficiency

Structural parameters

Core components

Demisting module: Diamond-shaped heat exchange design (superconducting carbon material, excellent thermal conductivity)

Filler: Oblique trapezoidal corrugated/special condensation module, high heat exchange efficiency

Fan: Axial flow, diameter 2400mm (some models)

Materials and weight

Tower body: Fiberglass shell (corrosion-resistant), frame optional steel structure/concrete structure

Weight: The large tower weighs several tons without load (specific model needs to match the manufacturer's data)

Performance and energy consumption

Demisting and water-saving capabilities

Annual average water saving rate: 15–20% (wet and hot air condensation recovery)

Plume elimination rate: Visual pollution can be completely eliminated in winter

Energy consumption characteristics

Summer operating power consumption is comparable to traditional industrial towers (heat exchange module switches to the hot channel)

The additional energy consumption of the winter demisting mode needs to be optimized in combination with the fan power consumption

Application scenarios and selection points

Applicable fields

Power plants, coal chemical industry, iron and steel metallurgy (requires large-flow demisting)

Urban buildings, commercial complexes (low noise, water-saving requirements)

Key selection factors

Core parameters: circulating water volume, wet-bulb temperature, water saving rate

Scalability: Modular design supports later capacity expansion

Precautions

Environmental matching: Northern low-temperature areas need to optimize the antifreeze design of the condensation module

Operation and maintenance: Regularly clean the heat exchange module to prevent blockage (affecting water saving efficiency)

Noise control: Optimize the noise reduction device at the inlet and outlet (some models can reach low noise standards)

Equipment schematic diagram

Related Products

Online consultation

Contact Us

Address:Anqiu City, Weifang City, Shandong Province, China